1. Creation of new business models

By virtue of disruptive and innovative work, the 4.0 revolution has promoted profound changes

in different segments, which is why it has been responsible for the emergence of new opportunities

of business, even in traditional sectors such as agribusiness.

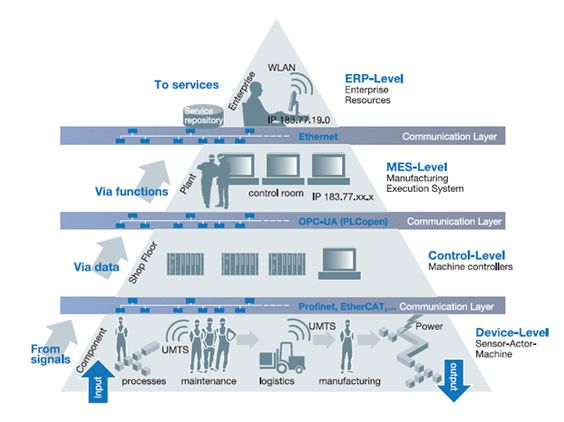

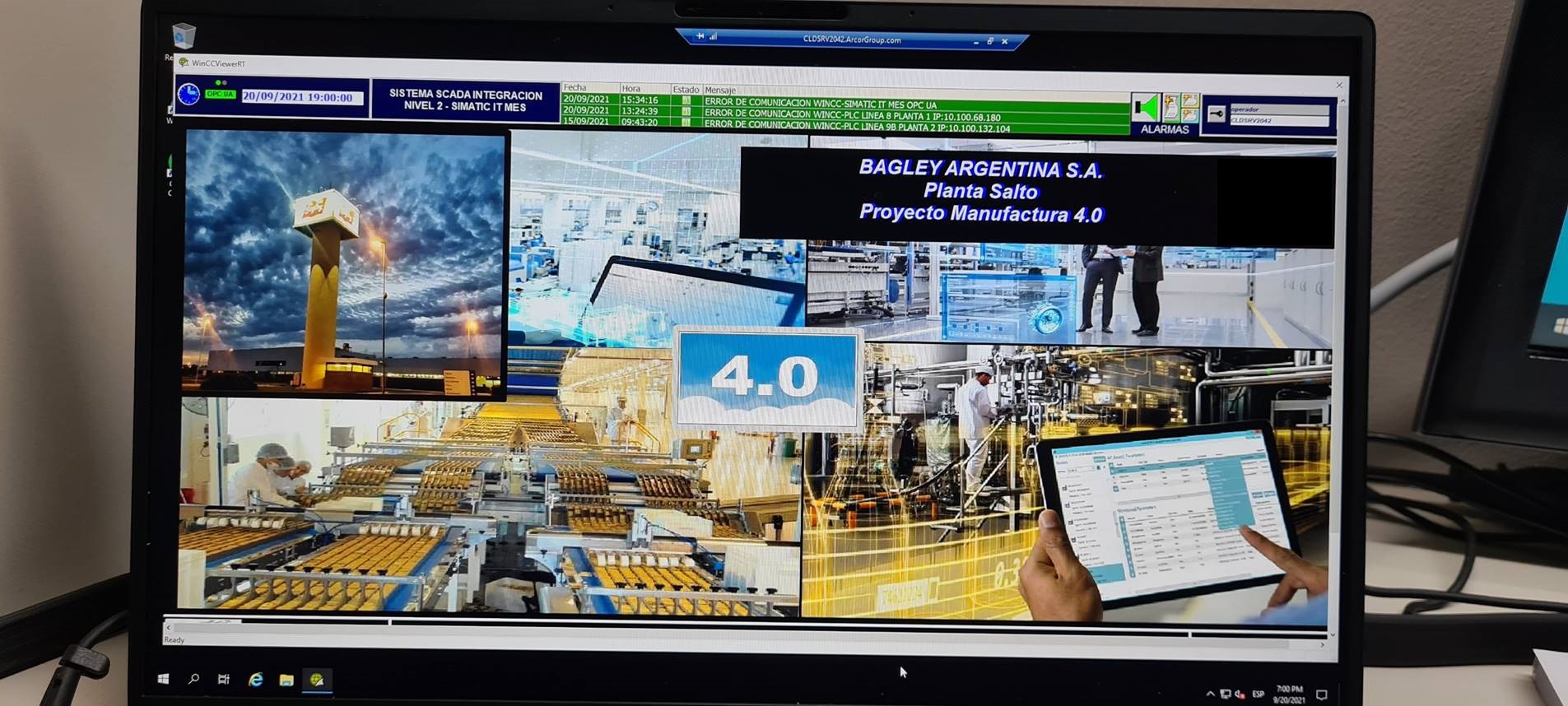

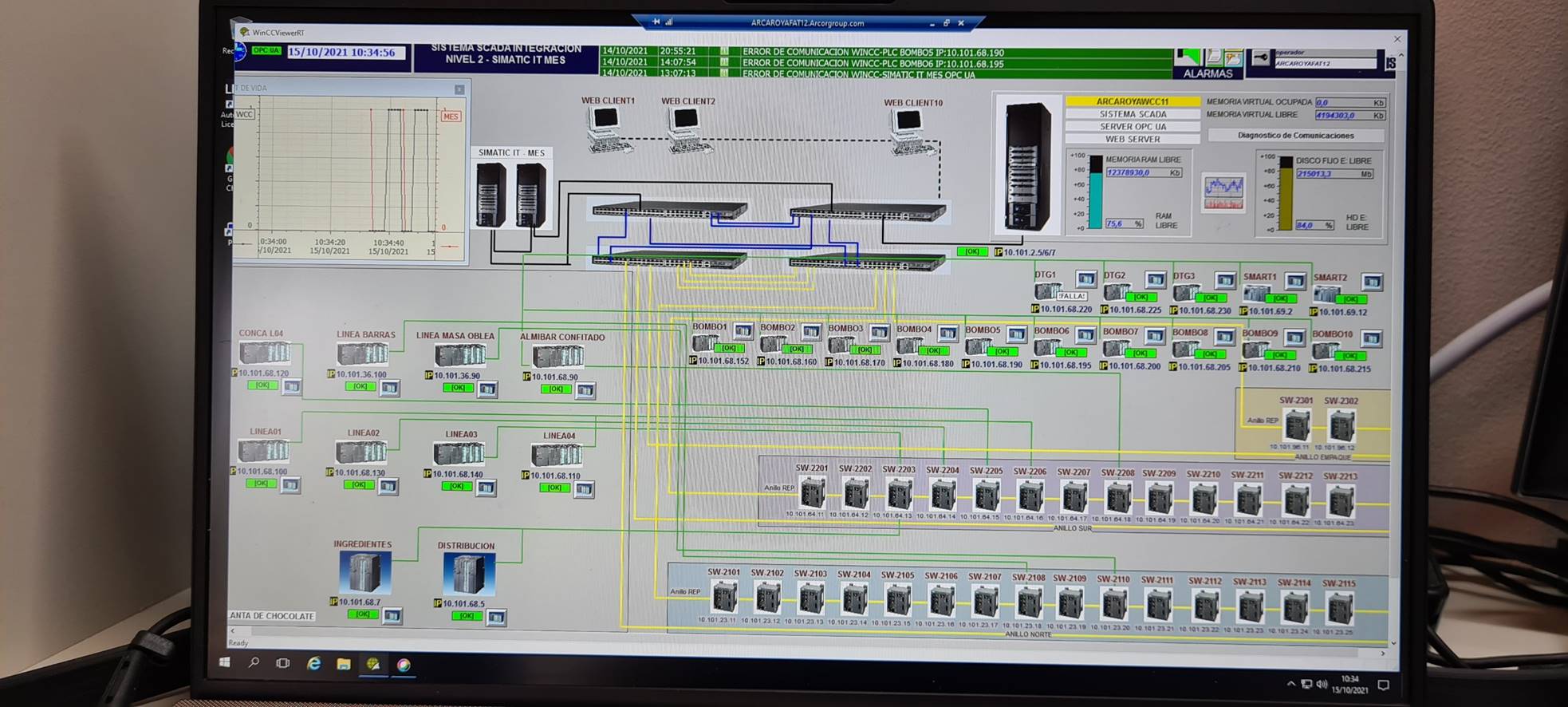

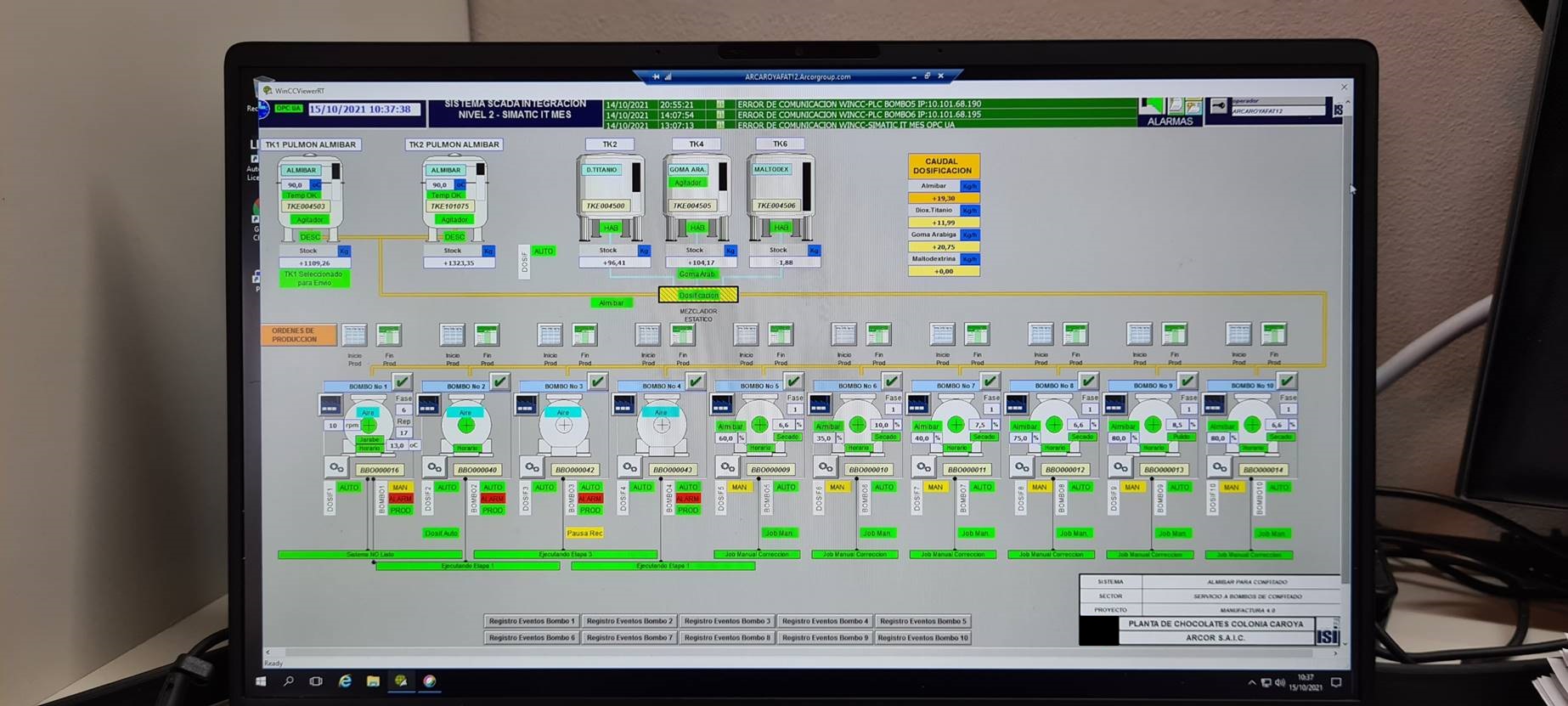

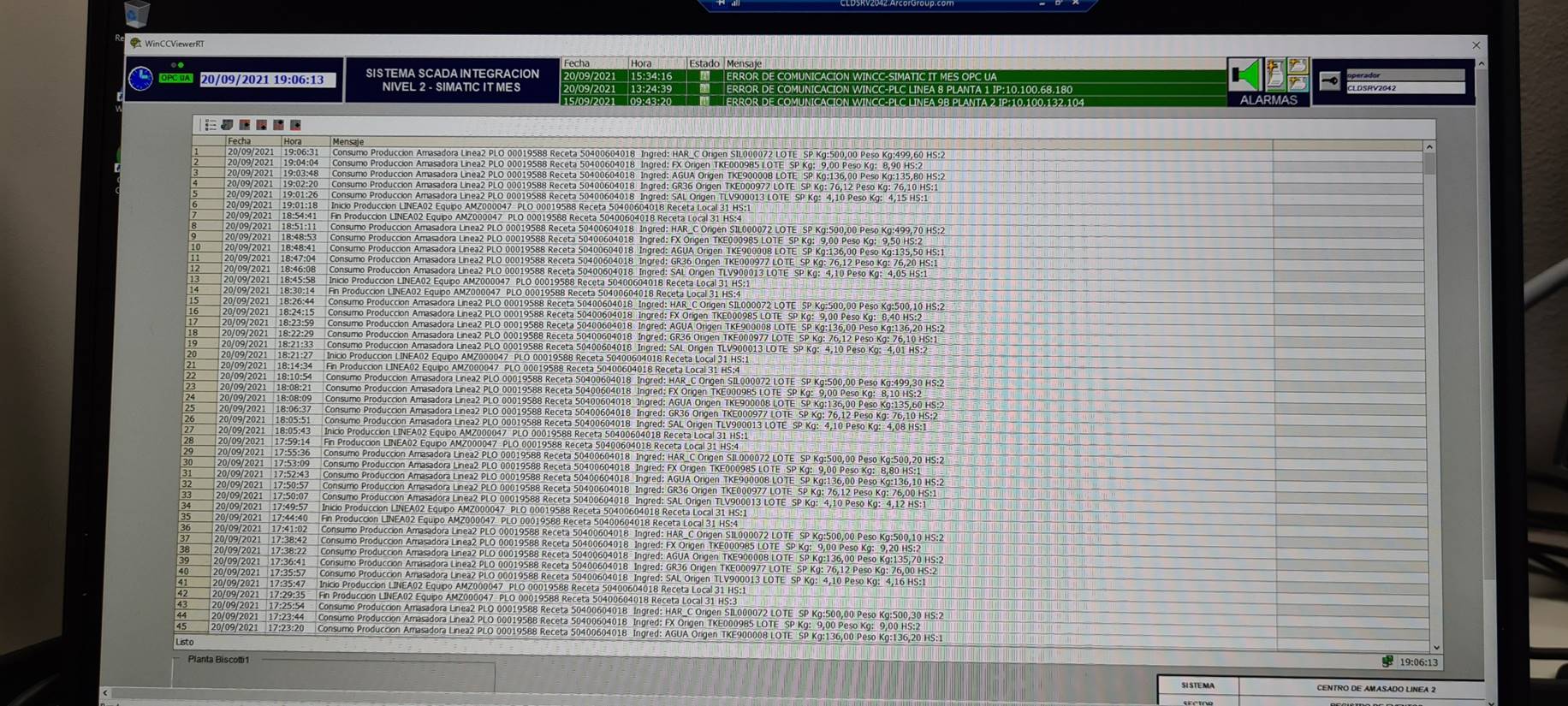

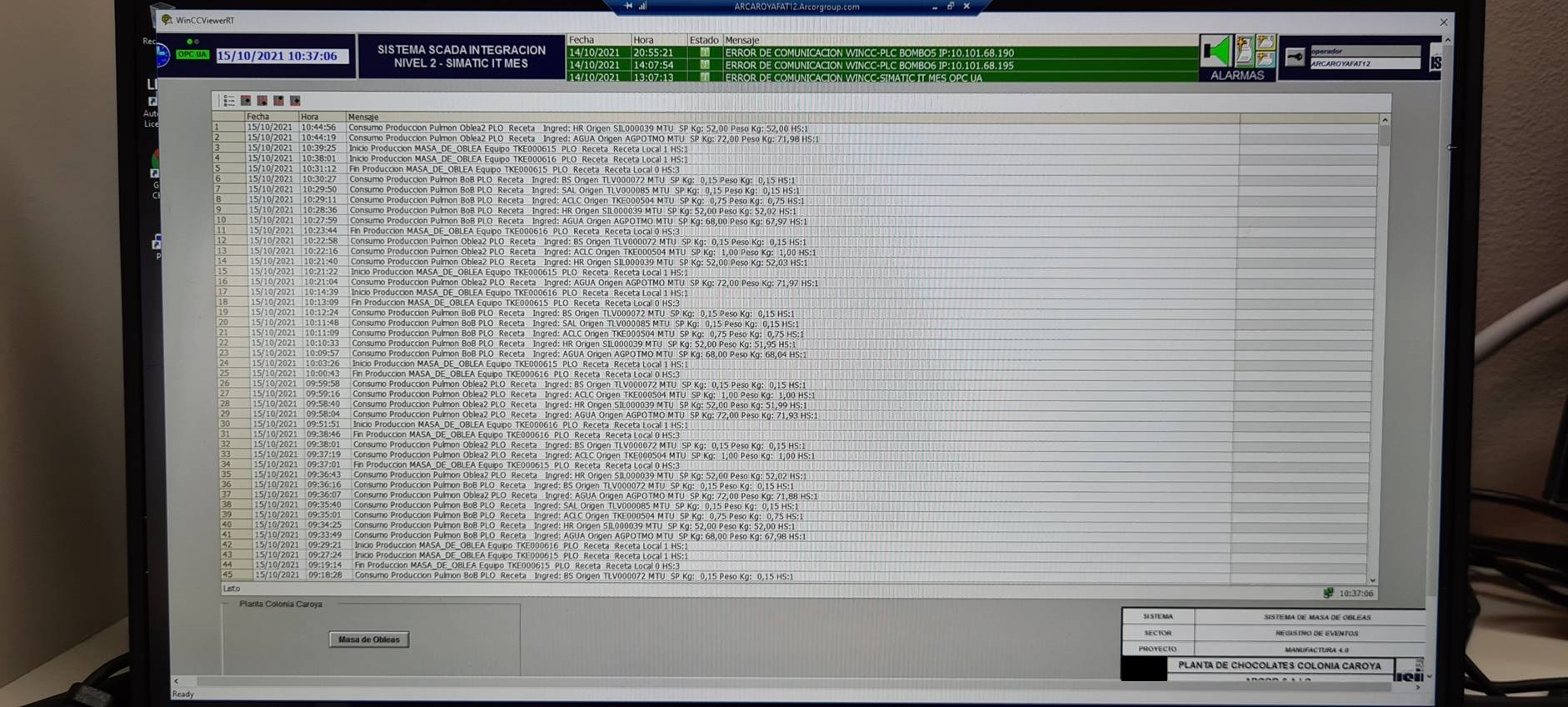

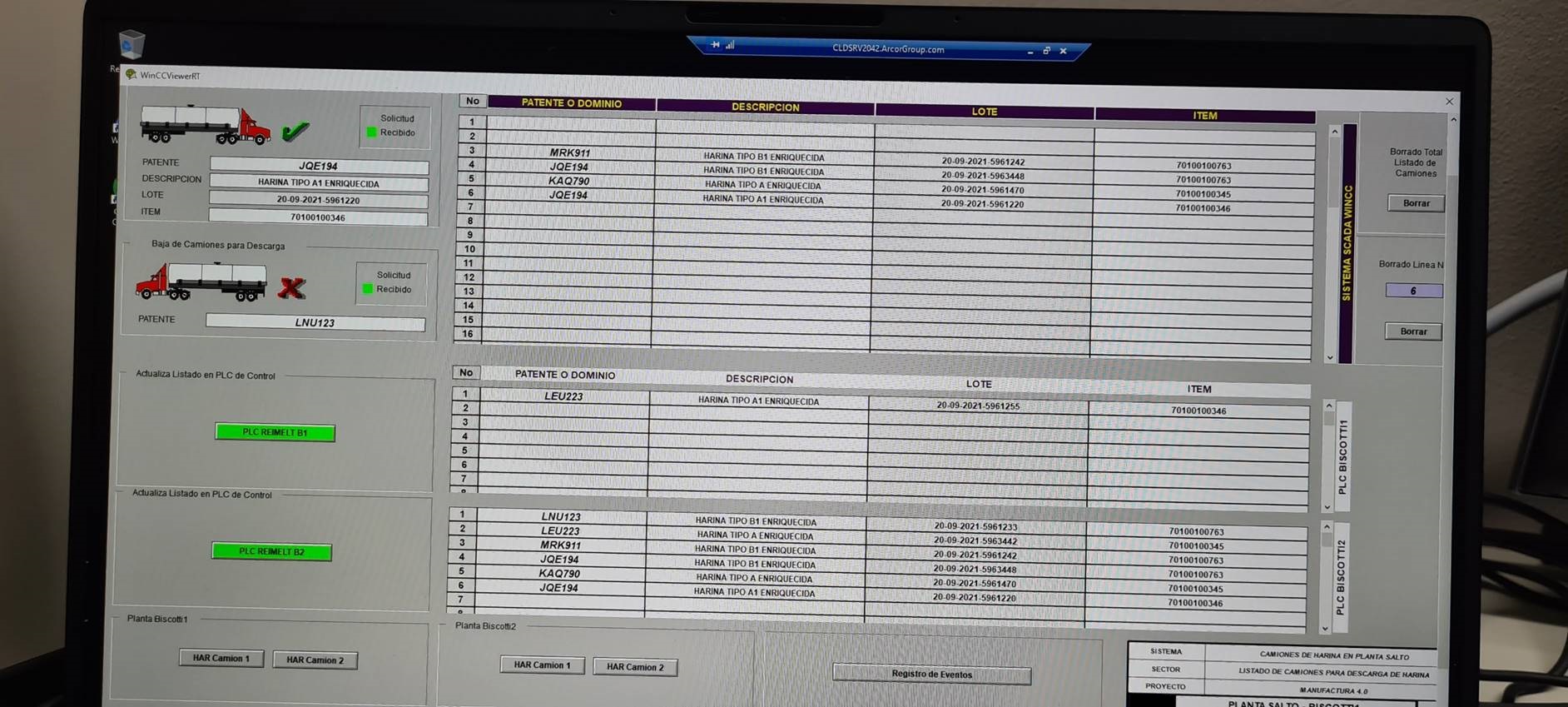

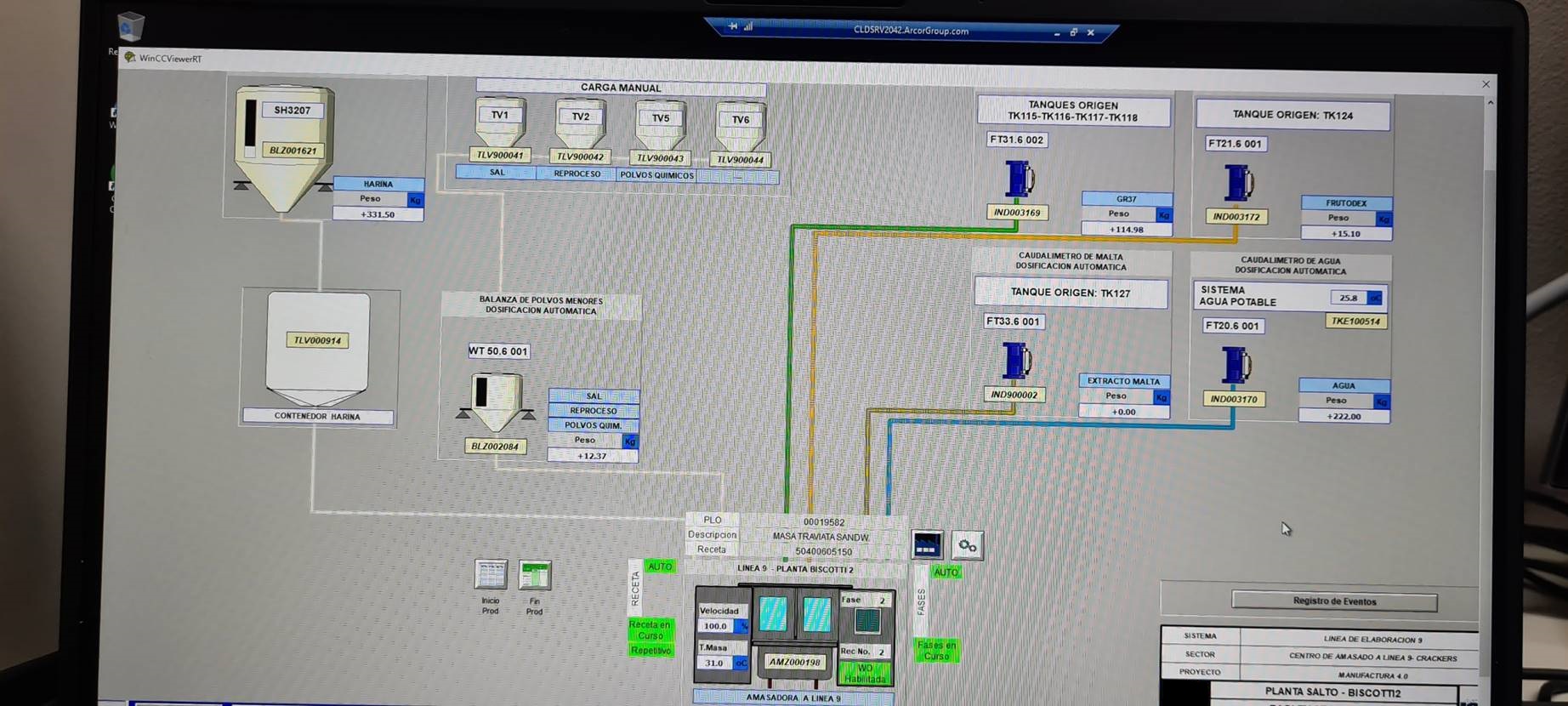

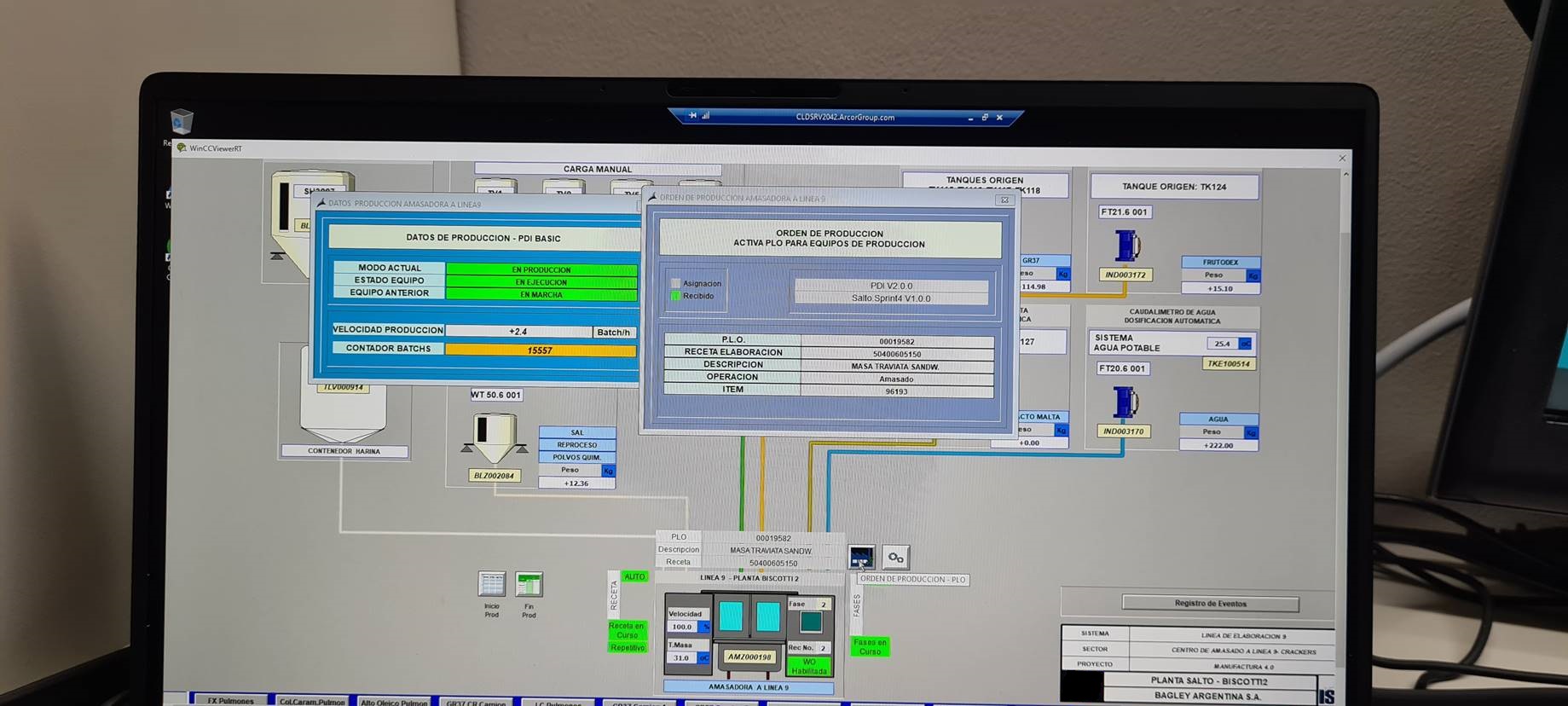

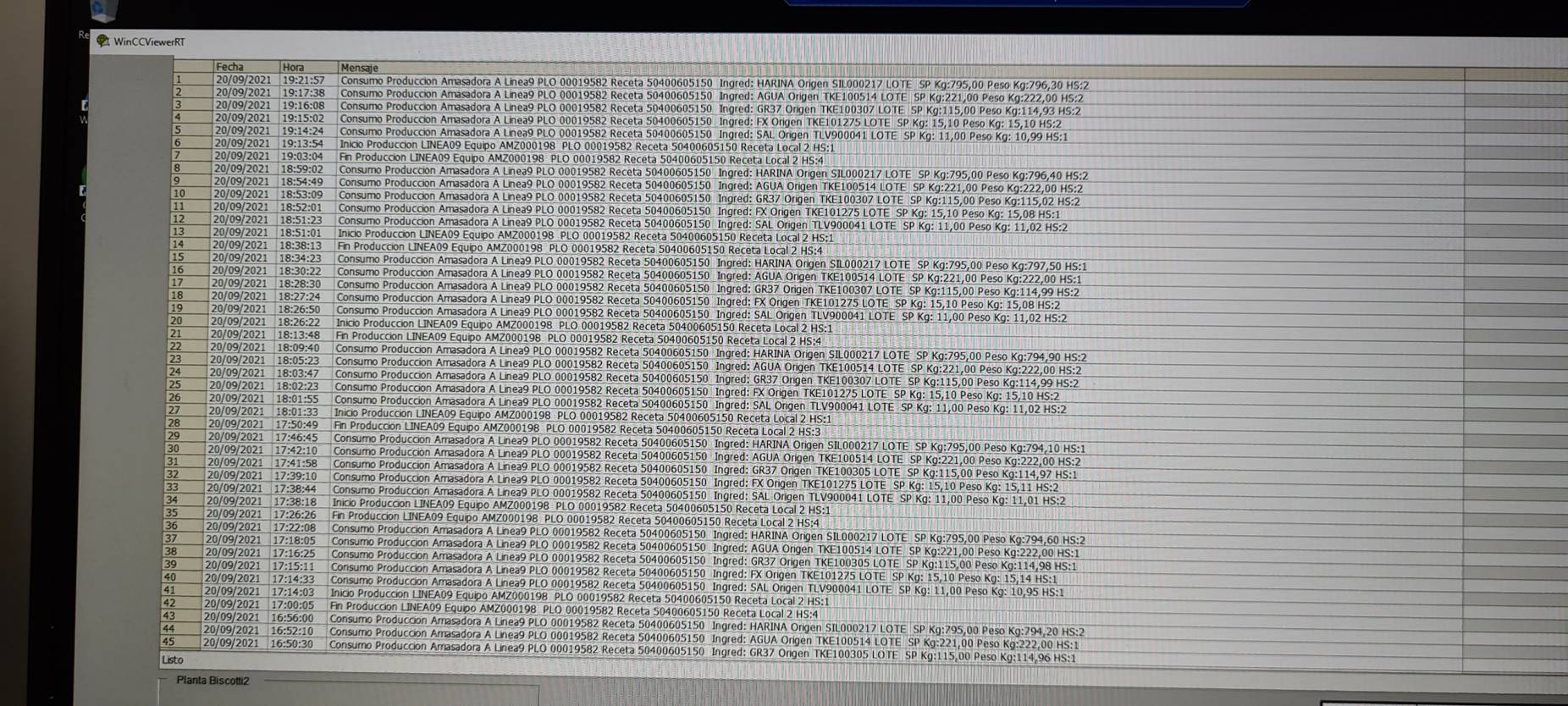

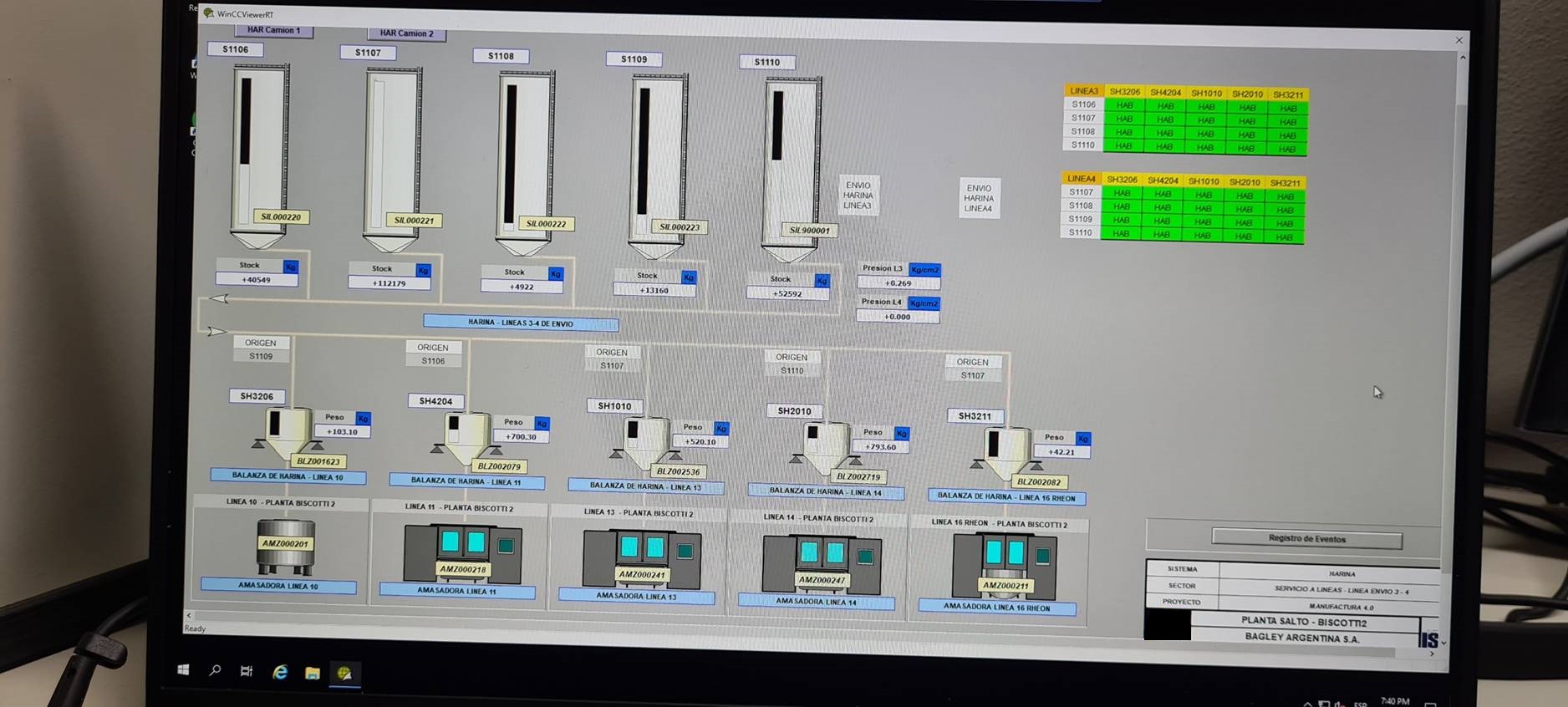

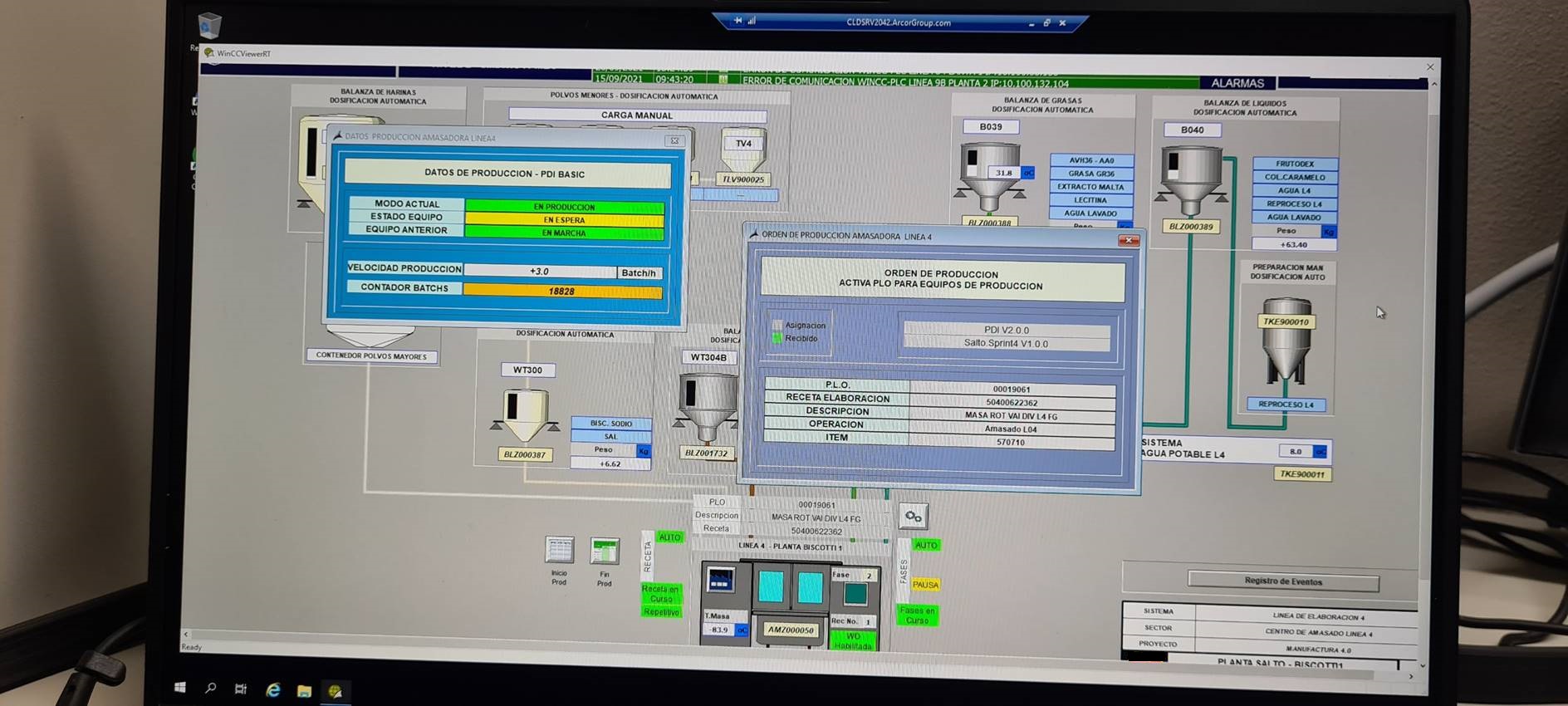

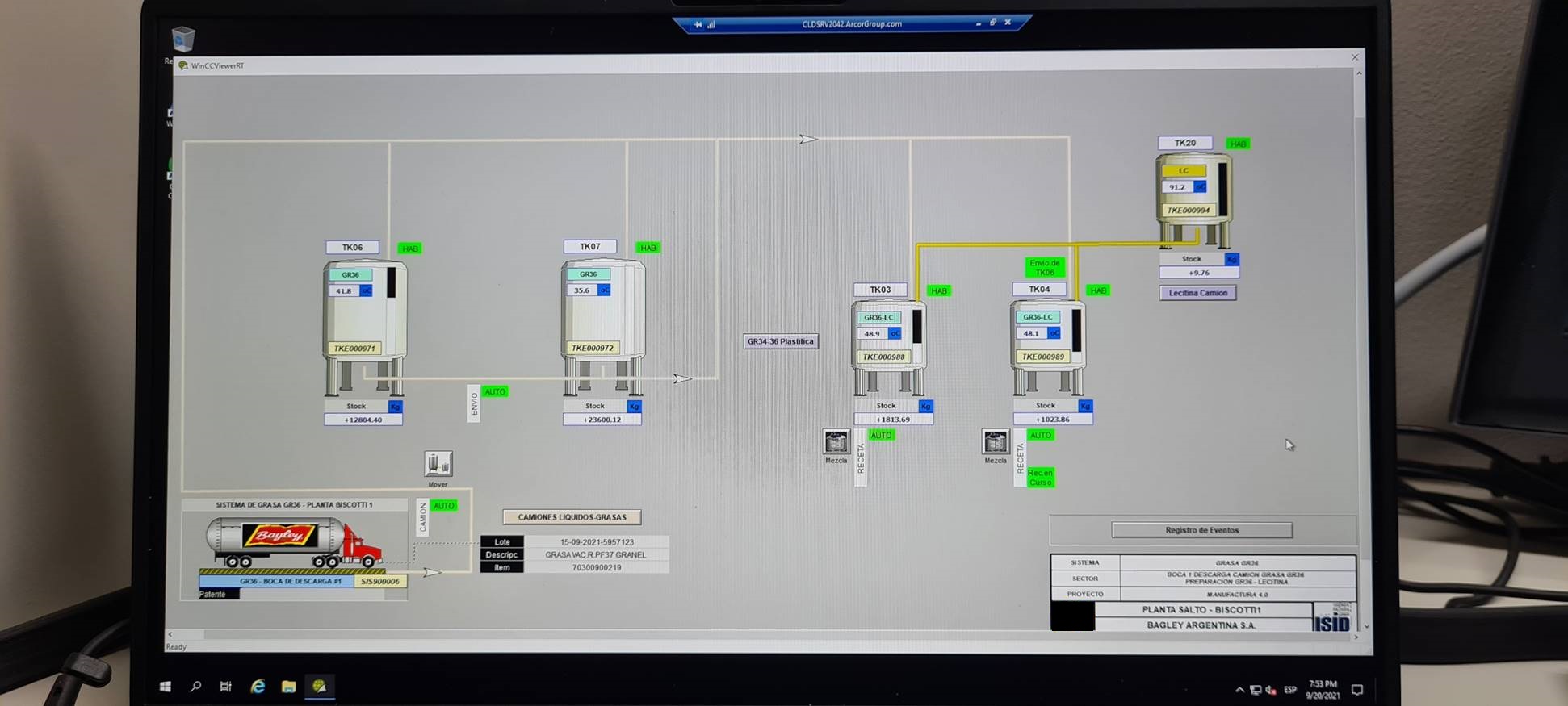

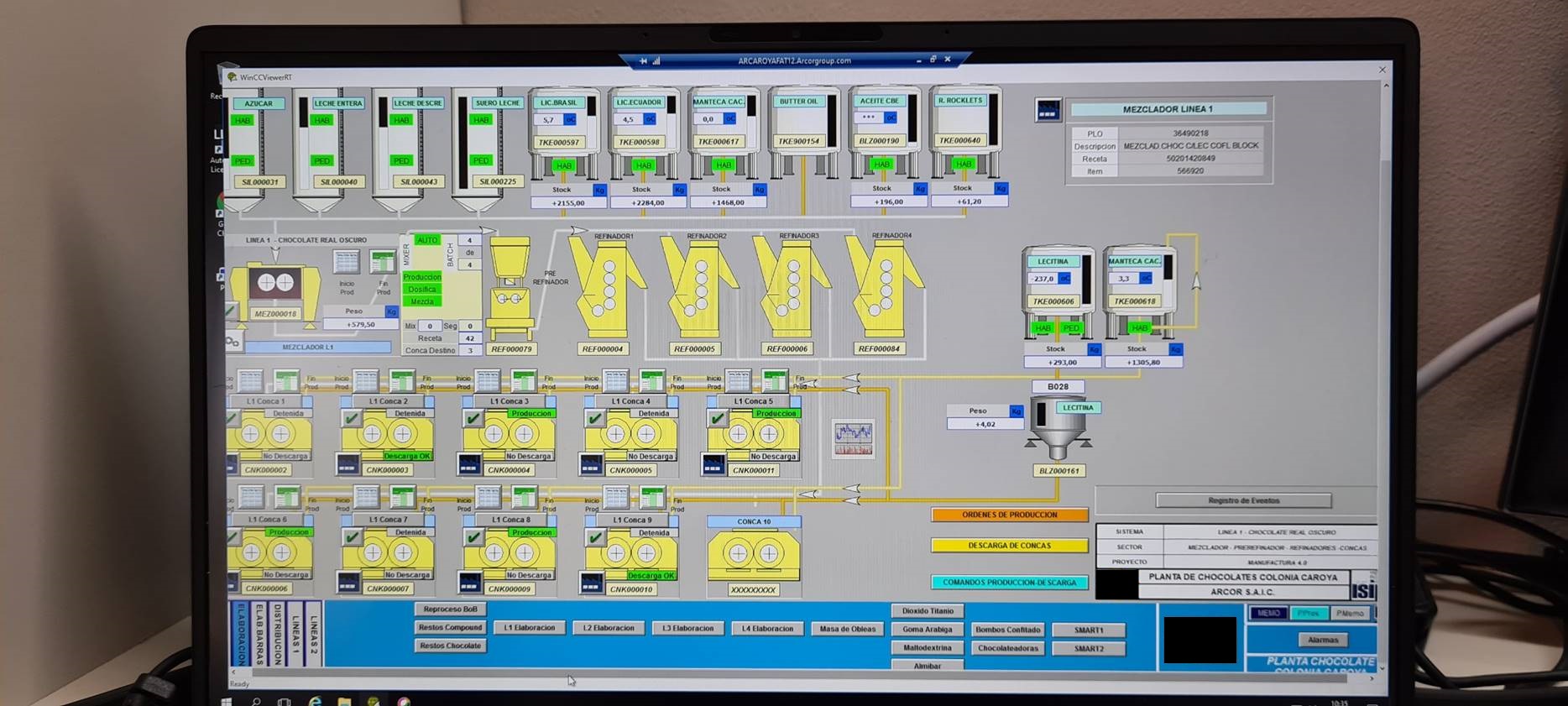

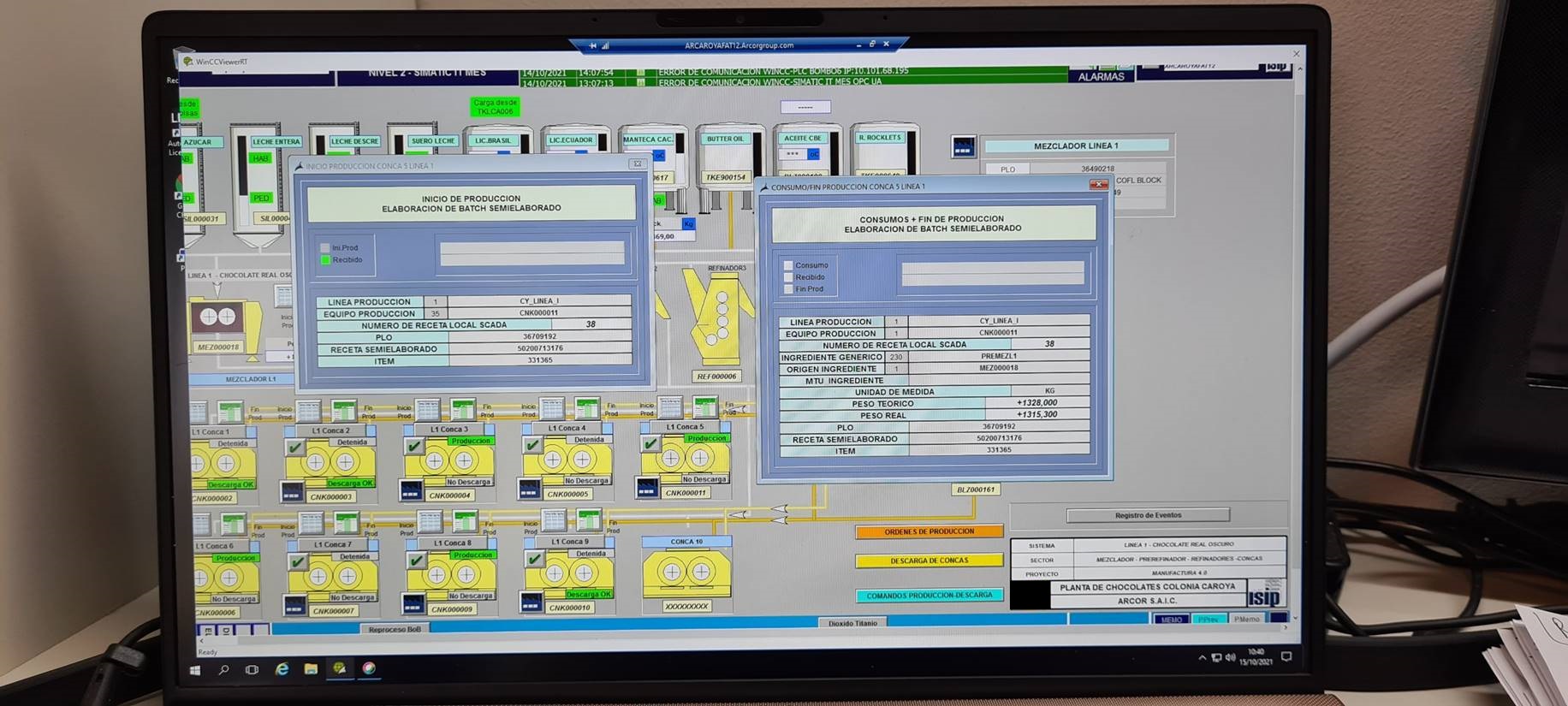

2. Real-time operations integration

Smart factories are characterized by the rapid processing of information, positioning themselves,

in this way, as another relevant differential of industry 4.0.

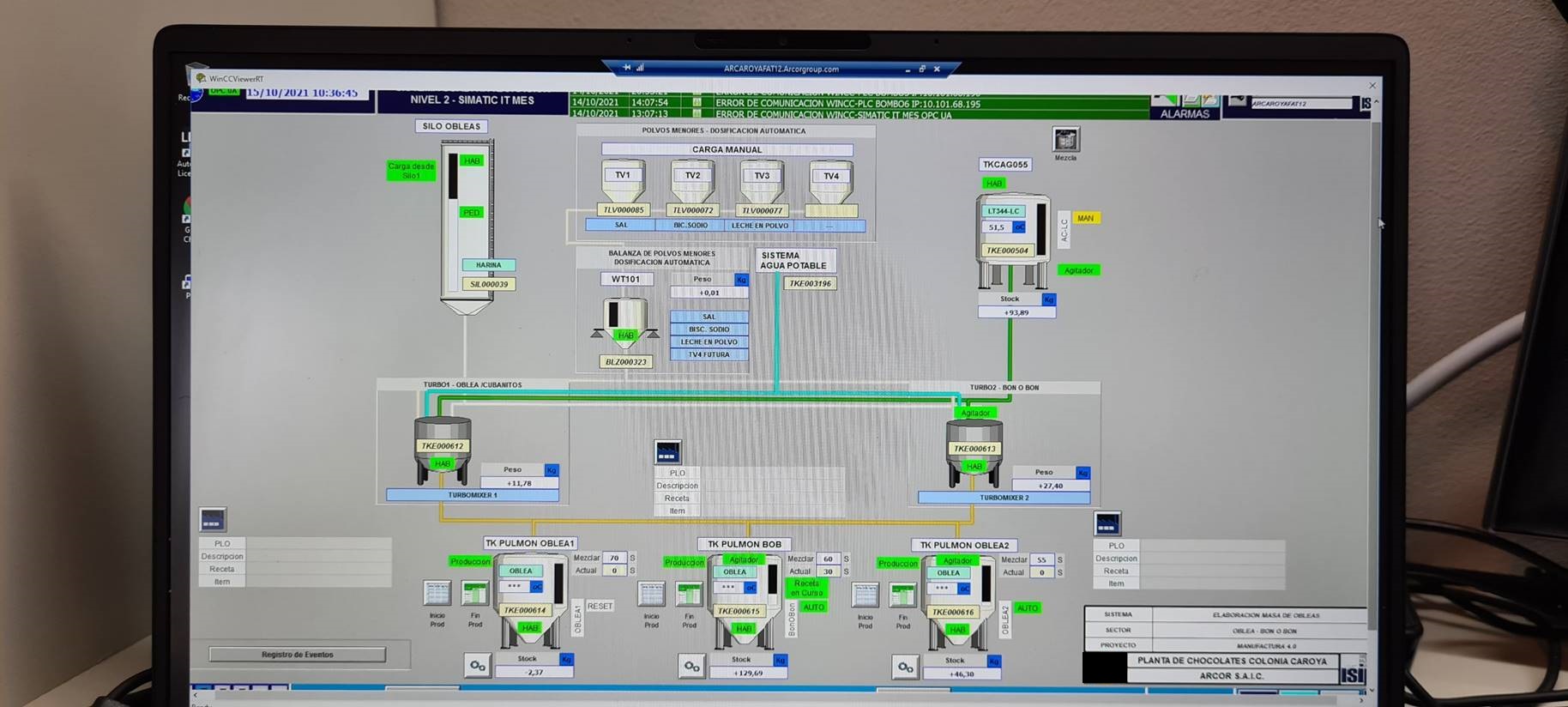

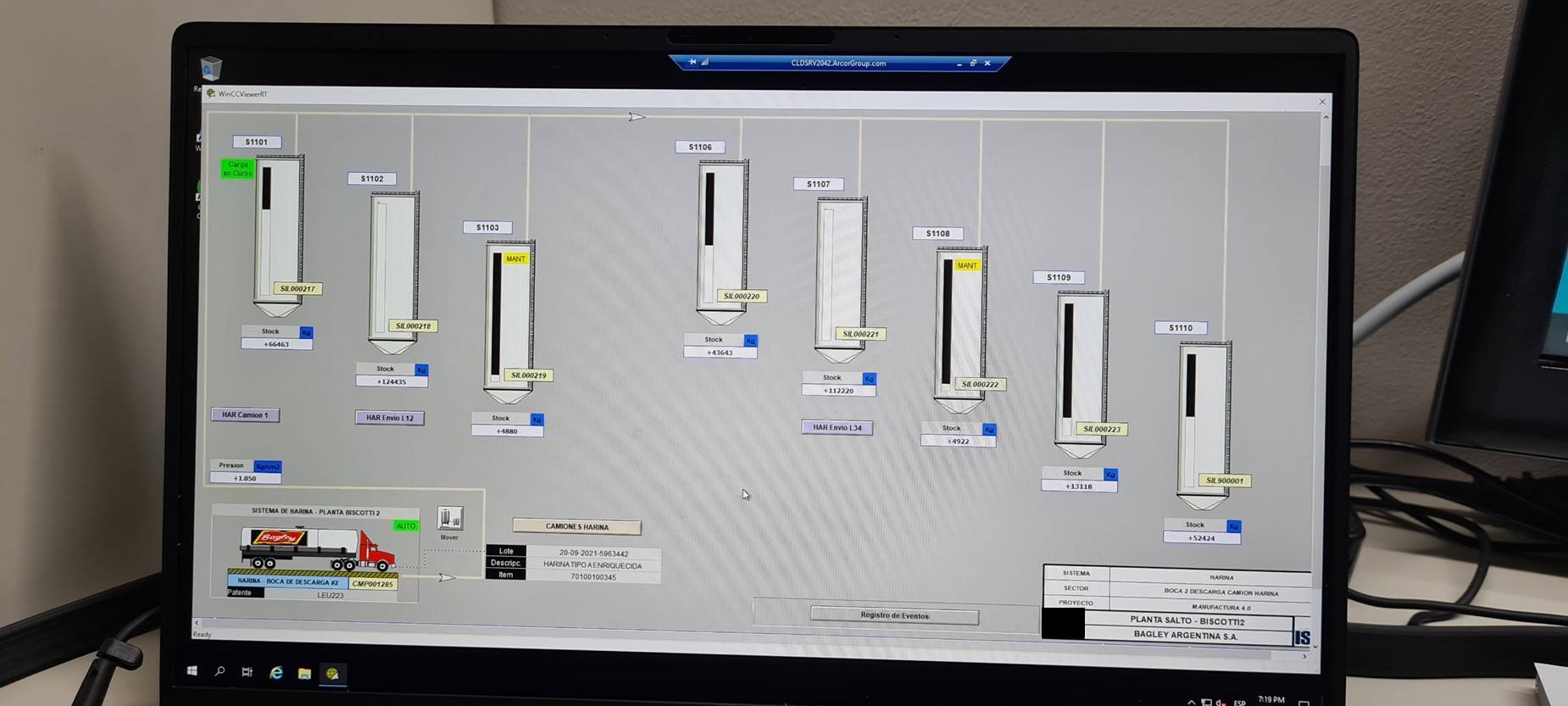

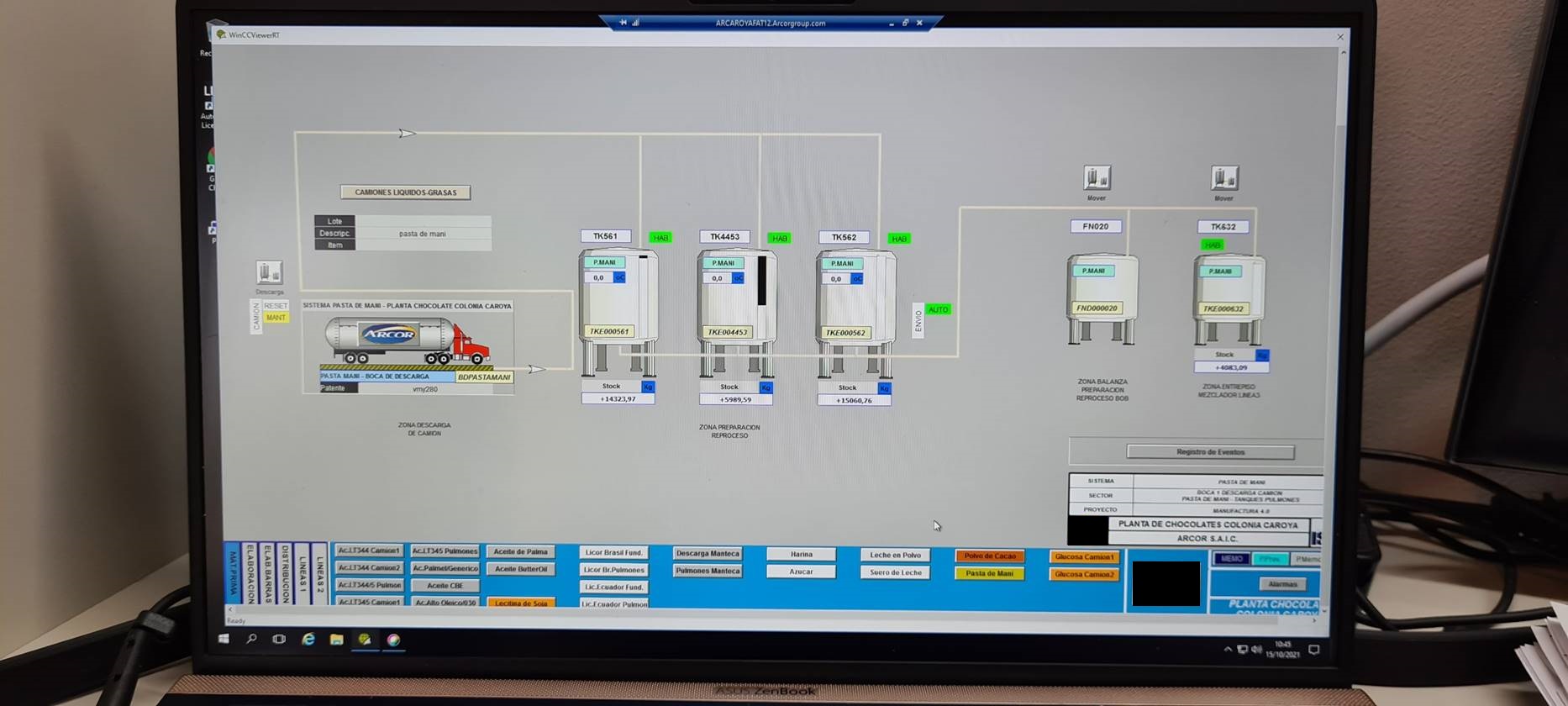

By adopting artificial intelligence technological tools, it is possible to monitor the

teams remotely and in real time, thus increasing the transparency of processes and optimizing

the availability of data.

3. Costs reduction

The typical resources of Industry 4.0 make it possible for the machines themselves to operate and schedule maintenance

autonomously, mitigating the need to hire personnel to manually carry out this type of activity.

As a consequence, the industry manages to reduce the budget oriented to the operational field, focus resources

towards actions that promote productivity and, consequently, improve business results.

4. Energy economy

Electrical energy costs are one of the most significant expenses at an industrial level, so reducing them

It has become a must for businesses that want to improve their efficiency and take their profitability to the next level.

Thanks to technology, most industrial equipment has sensors that detect activity

remaining fully operational as long as necessary and ceasing it during moments of leisure.

Likewise, technological advancement has favored the appearance of increasingly economical and energy-powered equipment.

renewable as is the case of solar.

5. Sustainability

By saving electrical energy, reducing the use of inputs by virtue of increasing efficiency and promoting consumption of

renewable energy, industry 4.0 has positioned itself as an ally of sustained development.

6. Reduction of errors

The reduction of human intervention in processes reduces the incidence of errors in industrial operations,

It is even possible to program the machines to achieve a minimum level of inefficiency.

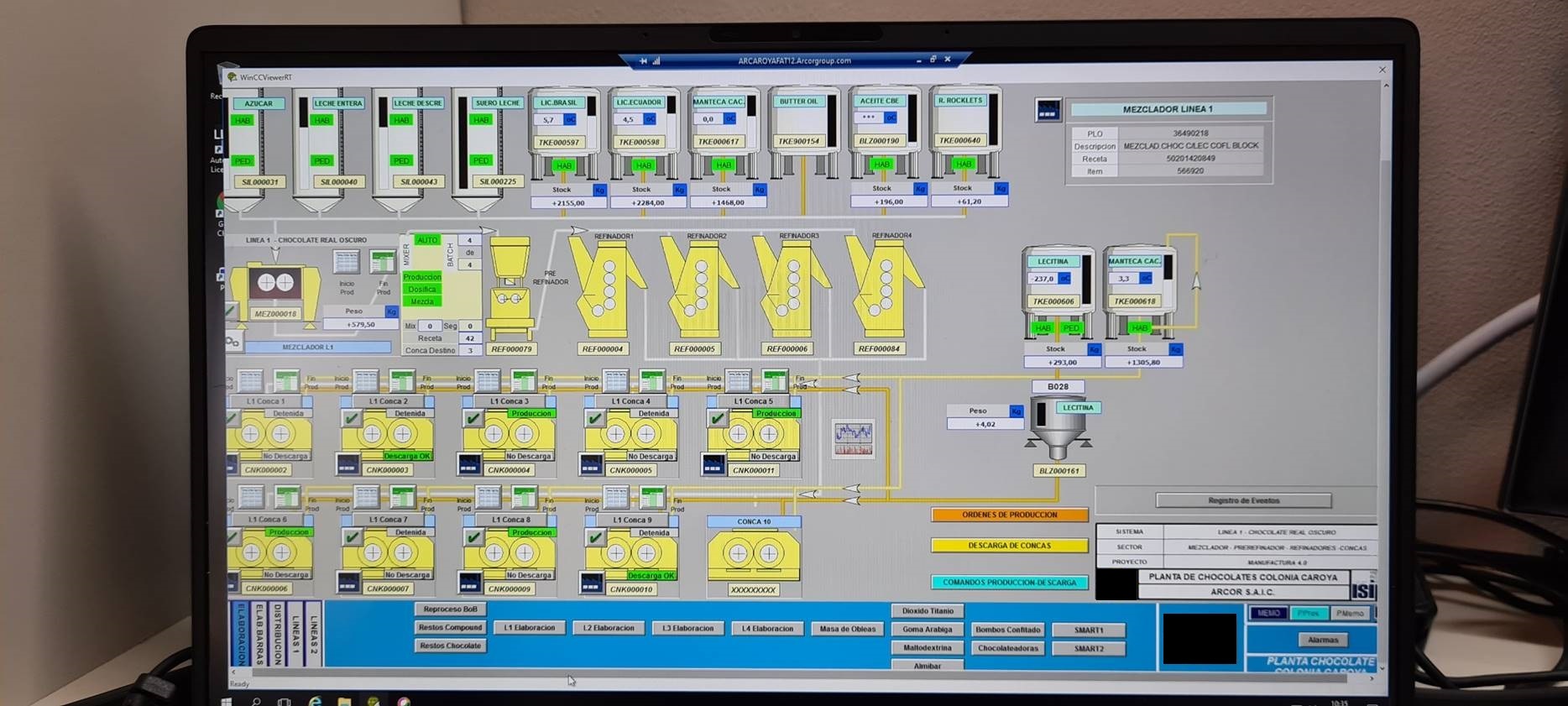

7. Productivity increase

Investment in technology allows different processes to be automated, thus promoting more agile and precise execution.

Indeed, the automation of repetitive tasks makes it possible to assign professionals to perform more complex tasks,

strategic, related to the core business, that really add value to the results and that are related

with business objectives.

8. Efficiency optimization

In addition to streamlining tasks and promoting the reduction of errors in the execution of processes, industry 4.0 promotes

use of resources in a more conscious, intelligent and economical way, resulting in increased operational efficiency

and in improving business performance indicators.